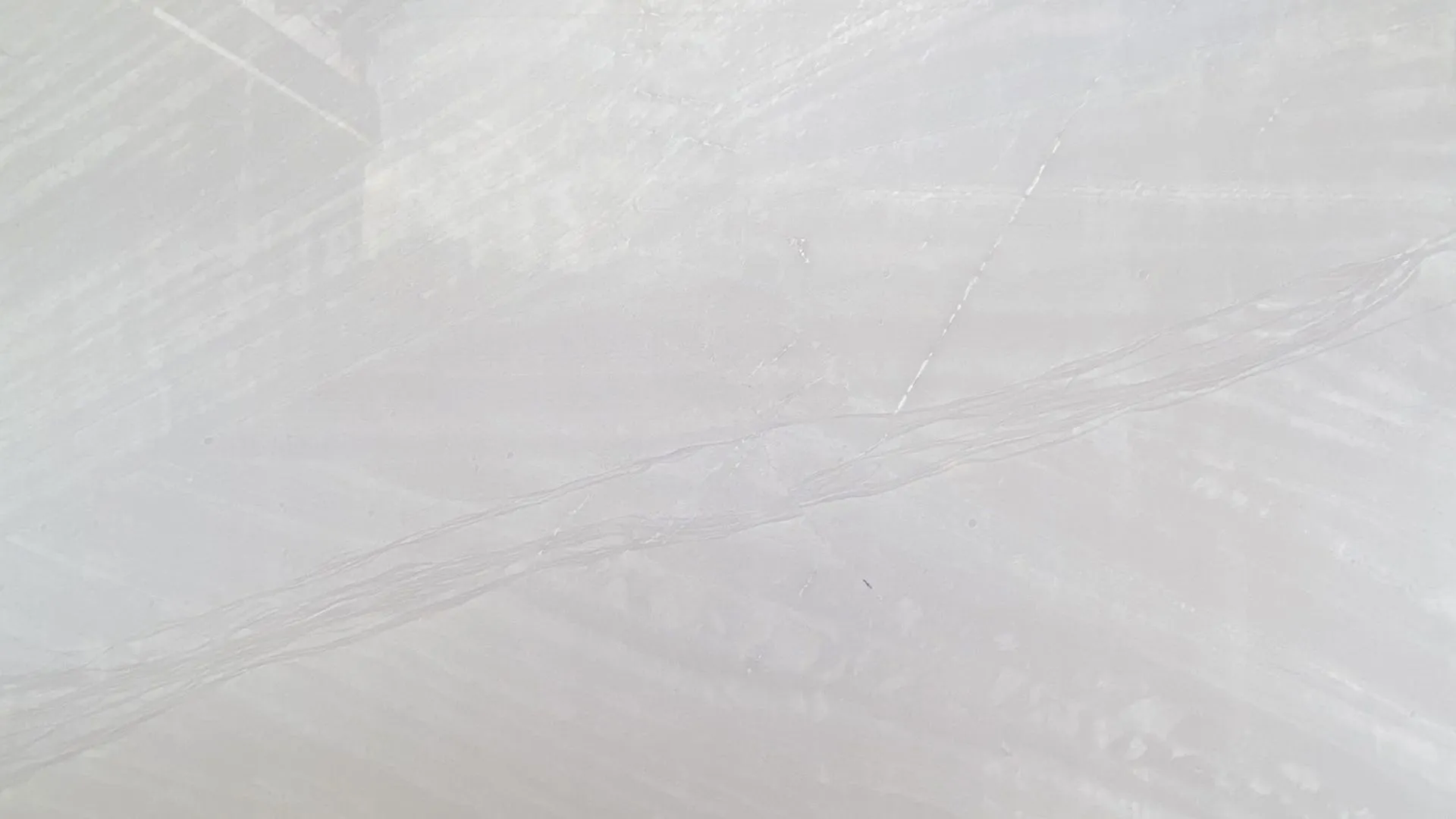

Madrid

Madrid is a type of Brazilian quartzite known for its elegance and durability. Below are some technical details and characteristics of this natural stone:

General Characteristics:

- Composition: Madrid is predominantly composed of quartz, which gives it great durability and resistance.

- Color: Its coloration is predominantly white, providing a clean and sophisticated look, ideal for various types of environments.

- Texture: It has a fine and homogeneous texture, with a smooth surface that can vary from polished to honed, depending on the chosen finish.

Applications:

- Interior: Due to its neutral and elegant appearance, Madrid is widely used in flooring and wall coverings, kitchen and bathroom countertops, as well as tables and benches.

- Exterior: It is also suitable for exterior applications, such as facades and floors, due to its resistance to weathering and wear.

Extraction Location:

- Madrid quartzite is mainly extracted in the southern region of Bahia, Brazil, highlighting the diversity and quality of Brazilian materials in the global market.

Care and Maintenance:

- Cleaning: To maintain its beauty and integrity, regular cleaning with water and neutral soap is recommended. Avoid abrasive or acidic products that may damage the surface.

- Sealing: The application of a suitable sealant can help protect the surface against stains and facilitate cleaning.

Installation:

- Cutting and Handling: Due to its hardness, cutting Madrid requires appropriate tools and experienced professionals to ensure a precise finish.

- Fixation: Installation should be carried out by qualified professionals using specific mortars and adhesives for natural stones, ensuring durability and safety.

Technical Analysis:

- Geological Classification: Madrid is classified as a quartzite, a type of metamorphic rock formed from the recrystallization of sandstone.

- Hardness: It has high hardness (around 7 on the Mohs scale), making it resistant to scratches and abrasions

Want to know more about this and other SuperClassico materials?

Faça sua pergunta para a nossa IA aqui!

BookMatching

Vertical

Vertical Horizontal

HorizontalFor Designers and Architects

| GEOLOGICAL CLASSIFICATION | QUARTZITE/QUARTZOLITE | |||

| TESTS | NORMA | RESULTS | SPECIFICATION ABNT NBR15844 | |

| Density | ABNT NBR15845:2 | 2.624kg/m³ | > 2.550 | |

| Porosity | ABNT NBR15845:2 | 0,20% | 1 | |

| Water Absortion | ABNT NBR15845:2 | 0,09% | < 0,4 | |

| Hard Body Impact | ABNT NBR15845:8 | 0,44m | < 0,3 | |

| Abrasion Strength | ABNT NBR12042 | 0,57m | < 1,0 | |

| Flexural Strength | ABNT NBR15845:7 | 9,3 MPa seco 6,2 MPa satu* | > 8,0 – | |

| Compressive Strength | ABNT NBR15845:5 | 234 MPa seco 199 MPa satu | > 100 – | |

| Rupture Module (3pts.) | ABNT NBR15845:6 | 12,9 MPa seco 13,2 MPa satu | > 100 – | |

| Module Rupture Associated with Freezing and Thawing | ABNT NBR15845:4 | 13,8 MPa | – | |

| Slip Resistance | EM14231 | 45 Baixo SRV* seco Alto SRV satu | – – | |

| 55 Baixo SRV* seco Alto SRV satu | – – | |||

| *SRV – slip resistance value (potencial deslizamento) *satu (saturado) | ||||

To simulate how a particular material would look as a floor, tabletop, or countertop in your home, use Augmented Reality technology on your smartphone. It’s easy! Just click on the “View in your space” button and you’ll be able to see the virtual object in your real environment. Try it now!

3D/AR View

Classification

Type: QUARTZOLITE

About

Madrid – A Natural Exotic Stone by SuperClássico Natural Stones

Composition

Surface Finishings

Polished

It is the “shiny” surface that results in the plate when receiving the complete finish, that is, until the last grain. Depending on its composition, the polished material may have a higher or lower brightness intensity.

Brushed

It is the resultant surface in the sheet when it receives roughing treatment performed by steel brushes or synthetic materials. Different brushing models can be executed, with greater roughness, medium and few.

Soft Leather

It is the resultant surface in the sheet when it receives roughing treatment performed by steel brushes or synthetic materials. Carried out with a brush of low roughness, which gives it a lightly textured look like fabric.

Flamed

It is the resultant surface in the plate when it receives heat treatment (burned with torch specially developed for the function) that takes out small flakes of the same, making the surface slightly irregular producing the impression that it is rustic.

Honed

It is the resultant surface on the sheet when receiving abrasive grinding wheels up to the grain 120. This grain defines the surface finish limit either as anti-slip or even for the application of resin and subsequent polishing.

Leather Finish

It is the resultant surface in the sheet when it receives roughing treatment performed by steel brushes or synthetic materials. Depending on the type of brushes used you can still reproduce in some materials a surface with a design similar to natural leather.