Bronzzo -Brazilian Exotic Natural Quartzite

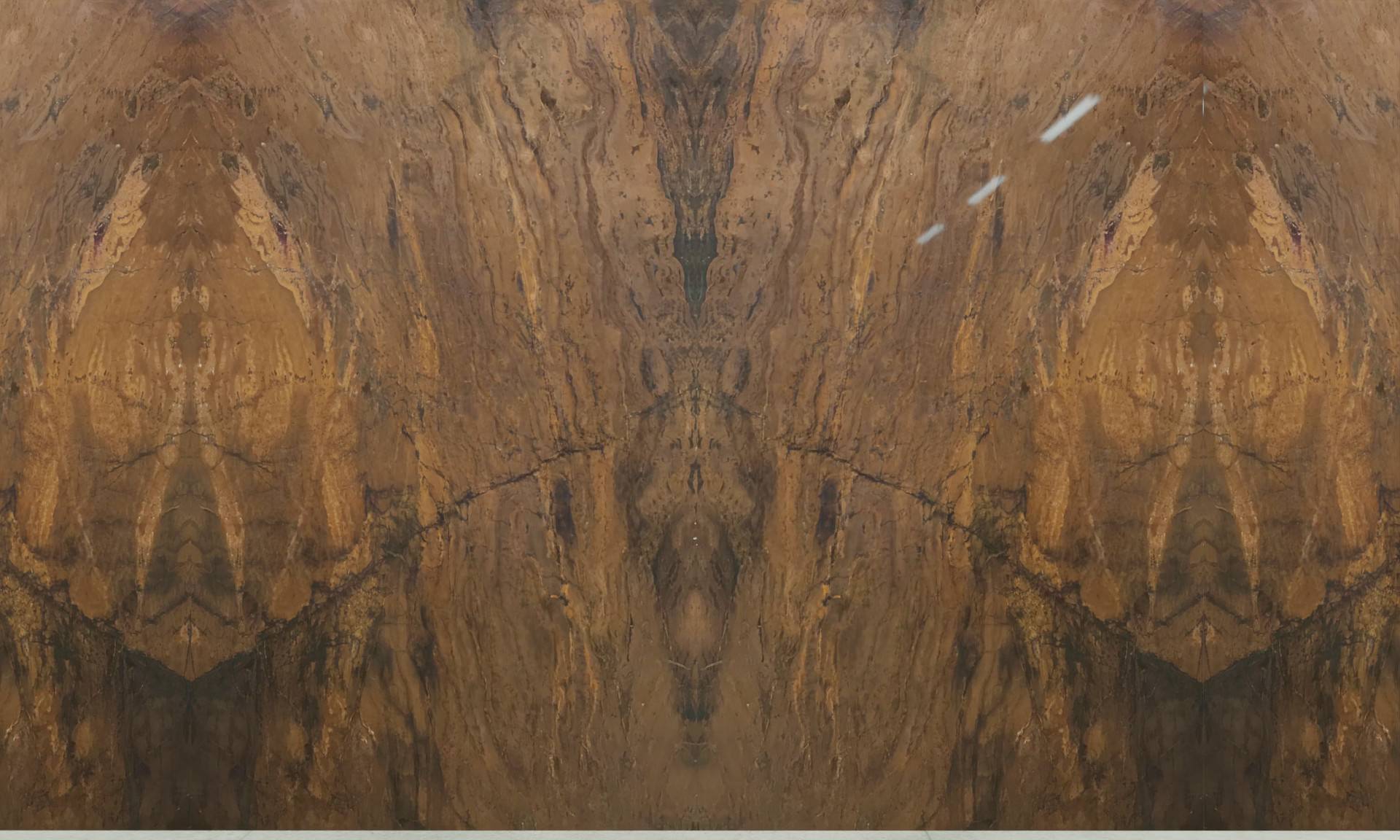

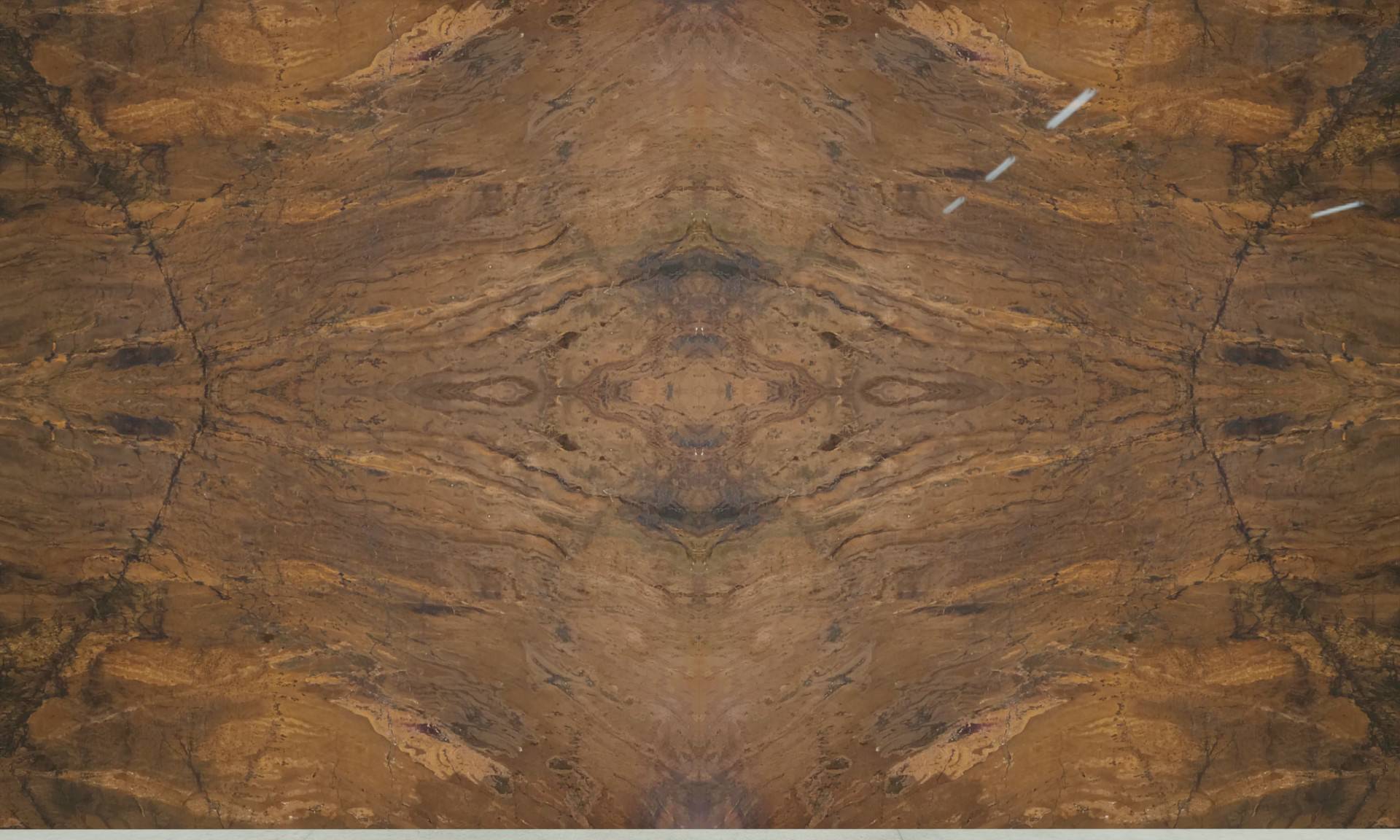

Bronzzo is a variety of quartzite with grunerite, extracted from the renowned quarries in the southern region of Bahia, Brazil. This quartzite is known for its unique appearance, blending a dark background with veins and patches in shades of brown and gold, evoking the look of wood. This combination results in a rustic, elegant, and sophisticated visual, making Bronzzo a popular choice for various design and architectural projects.

Characteristics of Bronzzo

Composition: Bronzzo is primarily composed of quartzite, with the presence of grunerite, a mineral from the amphibole group. Grunerite is responsible for the distinctive coloration of the stone, giving it its characteristic tones.

Texture: Bronzzo’s texture is homogeneous, with well-defined veins running through the surface of the stone. Depending on the finish, the surface can vary from polished to brushed, offering different tactile sensations and distinct visuals.

Color: Bronzzo’s predominant color is brown, with nuances of gold and black. This color palette gives the stone a luxurious and imposing appearance, ideal for environments seeking a touch of sophistication.

Uses of Bronzzo

Interior Cladding: Bronzzo is widely used in kitchen countertops, islands, washbasins, fireplaces, and decorative panels. Its durability and impressive aesthetics make it an excellent choice for these environments.

Floors and Walls: In addition to interior cladding, Bronzzo is suitable for floors and walls, providing elegance and resistance. The application on interior floors and walls transforms spaces, adding a touch of class and sturdiness.

Decoration: In decoration, Bronzzo is ideal for architectural details and decorative pieces, such as coffee tables and furniture tops. Its rustic and sophisticated appearance blends well with various interior design styles.

Maintenance and Care

Daily Cleaning: To maintain Bronzzo’s beauty, use a soft cloth and a neutral detergent for daily cleaning. Avoid abrasive products that can damage the polished surface of the stone.

Protection: Periodically sealing the stone is recommended to preserve its resistance to stains and liquids. This practice helps keep Bronzzo in excellent condition over time.

Special Care: Avoid contact with acidic or corrosive products, as they can damage the stone’s surface. Substances such as vinegar, lemon juice, and acidic cleaning products should be kept away from Bronzzo.

Extraction Site

Bronzzo is extracted in the southern region of Bahia, Brazil, an area known for the diversity and quality of its ornamental stones. The quarries in this region produce some of the most renowned and sought-after stones in the design and architecture market.

Technical Analysis

Hardness: Bronzzo has high hardness, a typical characteristic of quartzites. This property ensures durability and resistance to wear, making it an excellent choice for high-use areas.

Porosity: Bronzzo’s porosity is low, contributing to its resistance to stains and liquid absorption. This characteristic is particularly important in areas such as kitchens and bathrooms.

Resistance: With high resistance to impacts and scratches, Bronzzo is suitable for high-traffic areas. Its robustness ensures that the stone maintains its appearance and functionality for many years.

Conclusion

Bronzzo is an excellent choice for decoration projects that require a combination of beauty and durability. Its sophisticated aesthetics and physical properties make it a versatile and desired stone in architecture and interior design projects. Whether in interior cladding, floors, walls, or decorative pieces, Bronzzo stands out as a high-quality option that adds value and elegance to spaces.

Its various types of finishes leave it with a classic rustic and striking shape.

Want to know more about this and other SuperClassico materials?

Ask our AI your question here!

BookMatching

Vertical

Vertical Horizontal

HorizontalFor Designers and Architects

| PETROGRAPHY CLASSIFICATION | Gneiss Quartz-Grunerite | |

| NORMA | TESTS | RESULTS |

| ABNT NBR 12766 | Water Absorption | 0,15% |

| ABNT NBR 12766 | Apparent Dry Density | 3286 kg/m³ |

| ABNT NBR 12767 | Compressive Strength83 | 270,3 mpa |

| ABNT NBR 12763 | Flexural Strength | 38,9 mpa |

| Abrasion Strength | 0,001 (cm²/cm³) | |

To simulate how a particular material would look as a floor, tabletop, or countertop in your home, use Augmented Reality technology on your smartphone. It’s easy! Just click on the “View in your space” button and you’ll be able to see the virtual object in your real environment. Try it now!

3D/AR View

Click on the CARDS below and choose different options to simulate the material with AR in your environment through your Smartphone’s camera.

Classification

Tipo: QUARTZ / GRUNERITE

About

A material with a brownish tonality, formed by iron veins that refer to a rustic aspect of wood, but with quality and resistance of a Natural Stone formed millions of years ago.

Composition

Surface Finishings

Polished

It is the “shiny” surface that results in the plate when receiving the complete finish, that is, until the last grain. Depending on its composition, the polished material may have a higher or lower brightness intensity.

Brushed

It is the resultant surface in the sheet when it receives roughing treatment performed by steel brushes or synthetic materials. Different brushing models can be executed, with greater roughness, medium and few.

Soft Leather

It is the resultant surface in the sheet when it receives roughing treatment performed by steel brushes or synthetic materials. Carried out with a brush of low roughness, which gives it a lightly textured look like fabric.

Flamed

It is the resultant surface in the plate when it receives heat treatment (burned with torch specially developed for the function) that takes out small flakes of the same, making the surface slightly irregular producing the impression that it is rustic.

Honed

It is the resultant surface on the sheet when receiving abrasive grinding wheels up to the grain 120. This grain defines the surface finish limit either as anti-slip or even for the application of resin and subsequent polishing.

Leather Finish

It is the resultant surface in the sheet when it receives roughing treatment performed by steel brushes or synthetic materials. Depending on the type of brushes used you can still reproduce in some materials a surface with a design similar to natural leather.